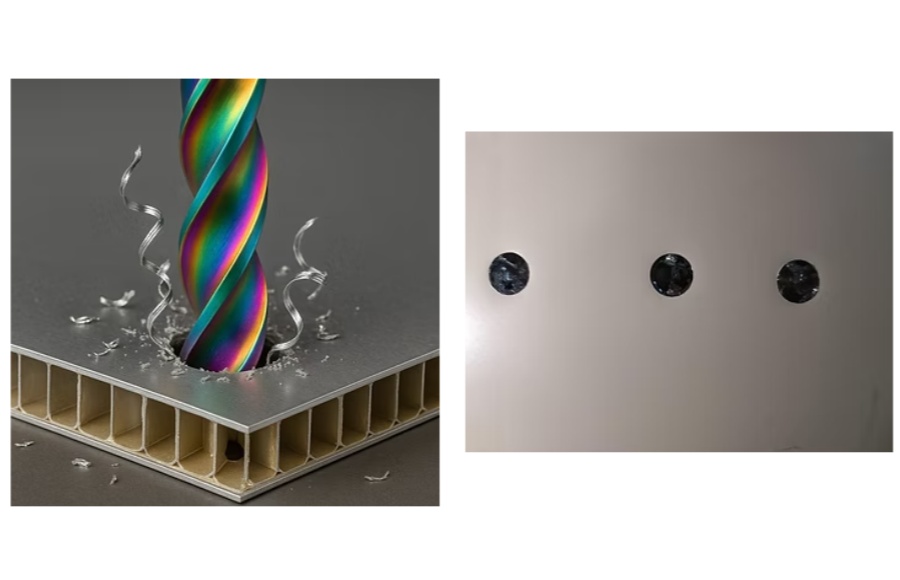

Honeycomb Aluminum Special Drill Bit

Publish Time: 2025-05-07

Most of the traditional commercially available drill bits were developed for the panel furniture processing technology more than ten years ago. The design has been finalized and it is difficult to meet the processing needs of new materials. Honeycomb aluminum plate (Honeycomb Aluminum Plate) is a lightweight material widely used in high-end furniture, aviation, rail transportation and other fields in recent years. Its special structure brings new challenges to drilling processing.Common problems in honeycomb aluminum processingIn the process of honeycomb aluminum plate processing, common problems include: bursting, panel collapse, sticking knife, incomplete cutting, wire drawing, low drilling efficiency or inability to drill, etc., which seriously affect product quality and processing efficiency. SolutionThe honeycomb aluminum special drill bit developed by LIHSING is specially designed for aluminum alloy and honeycomb aluminum composite structural materials. It adopts high-hardness cemented carbide substrate and combines advanced DLC coating technology. It has excellent wear resistance and anti-adhesion, which can effectively improve cutting efficiency, reduce processing temperature rise, and protect the integrity of honeycomb structure.Six-sided drilling processing scenario descriptionApplicable materials: aluminum alloy, honeycomb aluminum composite materialTool coating: DLC coating, anti-sticking toolApplicable equipment: CNC machining center, six-sided drilling machine, etc.Cooling method: air coolingRecommended speed: Through actual processing verification, the cutting temperature is low and the sticking phenomenon is less at 1800 RPM, which effectively protects the surface and internal structure integrity of the honeycomb aluminum plate.Feed speed: moderate and stable, with medium-speed feed (automatically adjusted according to the drill bit diameter and machine model), it can ensure accurate drilling size, no tearing on the edge, and smooth hole wall. Through actual processing verification, the feed and retract speed is recommended to be 500mm/min, which can obtain the best processing effectTool performance:No obvious chip stickingVery few burrs at the hole mouthNo obvious tearing or collapse of the honeycomb coreStable tool life, and the number of holes drilled reaches the expected number

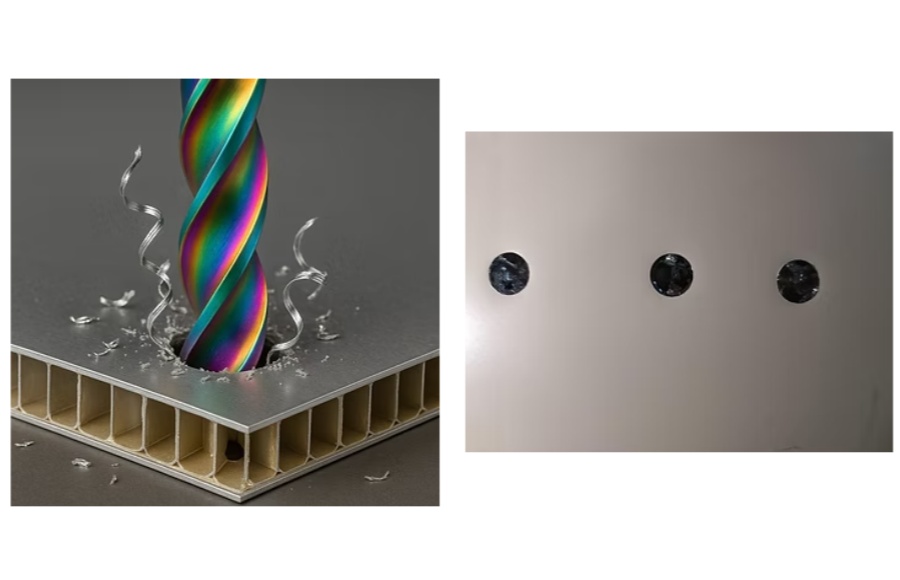

SolutionThe honeycomb aluminum special drill bit developed by LIHSING is specially designed for aluminum alloy and honeycomb aluminum composite structural materials. It adopts high-hardness cemented carbide substrate and combines advanced DLC coating technology. It has excellent wear resistance and anti-adhesion, which can effectively improve cutting efficiency, reduce processing temperature rise, and protect the integrity of honeycomb structure.Six-sided drilling processing scenario descriptionApplicable materials: aluminum alloy, honeycomb aluminum composite materialTool coating: DLC coating, anti-sticking toolApplicable equipment: CNC machining center, six-sided drilling machine, etc.Cooling method: air coolingRecommended speed: Through actual processing verification, the cutting temperature is low and the sticking phenomenon is less at 1800 RPM, which effectively protects the surface and internal structure integrity of the honeycomb aluminum plate.Feed speed: moderate and stable, with medium-speed feed (automatically adjusted according to the drill bit diameter and machine model), it can ensure accurate drilling size, no tearing on the edge, and smooth hole wall. Through actual processing verification, the feed and retract speed is recommended to be 500mm/min, which can obtain the best processing effectTool performance:No obvious chip stickingVery few burrs at the hole mouthNo obvious tearing or collapse of the honeycomb coreStable tool life, and the number of holes drilled reaches the expected number Technical adjustment suggestionsSpindle speed: Based on 1800 RPM, it can be adjusted to 1500~2000 RPM depending on the thickness of the plate and the honeycomb densityFeed and retract speed: It is recommended to control between 400~700 mm/min, and the specific adjustment shall be based on the actual cutting situation to ensure smooth cutting and avoid collapsing the panelCooling and chip removal: Maintain air cooling and use a blowing device to enhance the chip removal effectCommon problems and solutions during processingBurr problem: Since the material of honeycomb aluminum is relatively soft, burrs are prone to occur, especially at the hole mouth and the surrounding edges. The feed speed can be appropriately reduced, the cutting parameters can be optimized, and deburring can be performed after drilling if necessary.Honeycomb core collapse: If the honeycomb core collapses, it may be because the feed rate is too large or the drilling depth is too deep. The solution is to reduce the feed rate and use segmented drilling to disperse the cutting force and keep the cutting force evenly distributed. If the thickness of the aluminum alloy panel is less than 0.6mm, the solution will be answered in the next technical discussion, see www.lh80.com.tw for detailsChip management suggestionsChip removal direction control: Honeycomb aluminum chips are light and easy to fly. It is necessary to ensure that the processing equipment has a good chip removal channel to avoid chips interfering with the drilling areaChip cleaning frequency: The workpiece surface and tool should be cleaned regularly during processing to maintain a good cutting state and extend the tool lifeConclusionSix-sided drilling equipment is widely used in the modern furniture processing industry. When selecting equipment suitable for honeycomb aluminum plate processing, priority should be given to whether it is equipped with variable frequency speed regulation function. Equipment with this function can more flexibly adapt to the drilling needs of honeycomb aluminum plates, effectively deal with its processing difficulties, and ensure that product quality and production efficiency are equally important.

Technical adjustment suggestionsSpindle speed: Based on 1800 RPM, it can be adjusted to 1500~2000 RPM depending on the thickness of the plate and the honeycomb densityFeed and retract speed: It is recommended to control between 400~700 mm/min, and the specific adjustment shall be based on the actual cutting situation to ensure smooth cutting and avoid collapsing the panelCooling and chip removal: Maintain air cooling and use a blowing device to enhance the chip removal effectCommon problems and solutions during processingBurr problem: Since the material of honeycomb aluminum is relatively soft, burrs are prone to occur, especially at the hole mouth and the surrounding edges. The feed speed can be appropriately reduced, the cutting parameters can be optimized, and deburring can be performed after drilling if necessary.Honeycomb core collapse: If the honeycomb core collapses, it may be because the feed rate is too large or the drilling depth is too deep. The solution is to reduce the feed rate and use segmented drilling to disperse the cutting force and keep the cutting force evenly distributed. If the thickness of the aluminum alloy panel is less than 0.6mm, the solution will be answered in the next technical discussion, see www.lh80.com.tw for detailsChip management suggestionsChip removal direction control: Honeycomb aluminum chips are light and easy to fly. It is necessary to ensure that the processing equipment has a good chip removal channel to avoid chips interfering with the drilling areaChip cleaning frequency: The workpiece surface and tool should be cleaned regularly during processing to maintain a good cutting state and extend the tool lifeConclusionSix-sided drilling equipment is widely used in the modern furniture processing industry. When selecting equipment suitable for honeycomb aluminum plate processing, priority should be given to whether it is equipped with variable frequency speed regulation function. Equipment with this function can more flexibly adapt to the drilling needs of honeycomb aluminum plates, effectively deal with its processing difficulties, and ensure that product quality and production efficiency are equally important.